Laser Galvo Projector

Welcome to the exciting world of laser technology where precision, innovation, and advanced software combine to make magic.

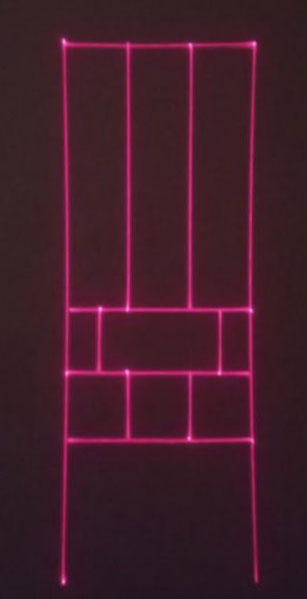

The Laser Galvo draws lines on the wall of a building during the construction process.

We are a small, dedicated team of experts who specialize in Laser Galvo Projectors. These devices are known for their accuracy, adaptability, and the incredible visual effects they produce.

- Entertainment: If you've been mesmerized by the amazing light shows at concerts or festivals, chances are, our laser galvanometers were part of the magic. We focus on creating stunning visual effects that are sure to captivate audiences.

- Manufacturing and Warehouses: In these environments, precision is critical. Our devices help with accurate marking and inventory tracking, ensuring smooth, efficient operations. Film Production: Our devices have been invaluable on film sets, helping create precise markings and contribute to impressive visual effects that reel in audiences.

- Construction: Building sites benefit greatly from our laser galvanometers. They aid in marking out sites and illuminating structures accurately, ensuring a smooth building process.

- Advertising: Step out of traditional advertising norms with our laser galvanometers. Use them to project creative and memorable images on any surface, making your ad campaigns unforgettable.

Our team's unique technical skills help us take laser galvanometers to the next level. In entertainment settings, we focus on creating eye-catching light displays, but when it comes to more demanding settings like factories and warehouses, we utilize advanced software to calibrate the galvanometers, achieving impressive precision.

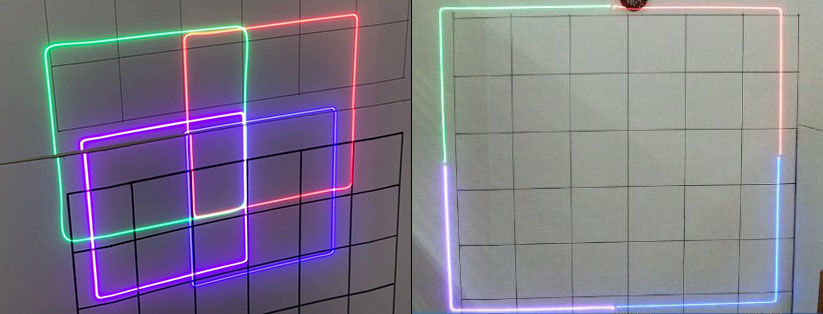

Several Laser Galvo units works as a single unit to project over a larger area

Left: each unit works independently, right: units working together increasing projected area

There are situations where one laser galvanometer might not be enough. Let's say you need to draw on a large area or need lots of lines drawn quickly. With just one device, you might see flickering. But don't worry, we've got a solution. We can connect several galvanometers and control them through a central server. This setup gives you the precision of multiple devices with the simplicity of operating just one.

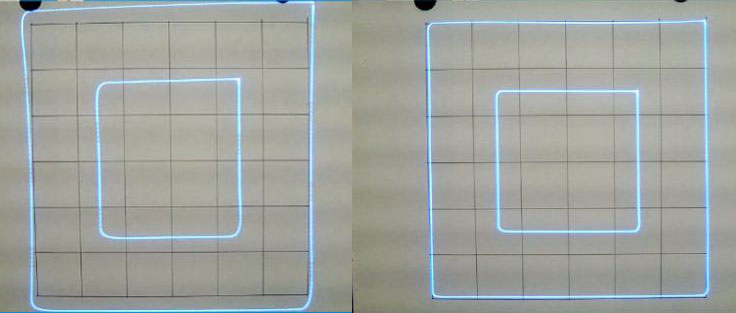

The software of the Laser Galvo refines the drawn lines to ensure they are straight.

Left: correction is off, right: correction is on

Setting up a galvanometer perfectly straight can be challenging and if not done right, it could lead to distorted images. That's why we've developed special software alignment methods to correct any distortions, ensuring the high-quality projections.

Laser safety

We totally understand, safety comes first, especially when dealing with lasers. Nobody wants a laser accidentally shining in their eyes! That's why we've got you covered with two important safety features in our Laser Galvo units. The first one is a proximity sensor. This smart little device turns off the laser right away if it senses someone getting too close to the beam. The second feature is an accelerometer sensor. This one makes sure that if the unit gets bumped or moved unexpectedly, the laser will switch off straight away. It's our way of making sure everyone stays safe while using our equipment.

Technical specifications

- Source:Full-color RGB semiconductor laser

- Output power:300 mw (R - 120 mw, G - 50 mw, B - 130 mw). A different laser can be installed by request.

- Laser colors: Red, Green, Blue, independently controlled

- Laser class:3. Output power can be hardware reduced by request.

- Single unit scanning angle: ± 20°. Multiple units can be utilized to cover larger area.

- Scanner speed: 20 Kpps @ 8°. See below for explanation

- Divergence of the laser beam : <1 mrad.

- Repeatability: 8 microradians

- Spot size: 1- 10mm, depending on distance

- Control:USB via computer GUI, WiFi, DMX, BlueTooth (Smartphone). API is available for custome control

- Number of units connected to the server:8

- Max power:50W single unit

- Power input:110V, 60 Hz. Different power input can be used by request, for example, 24V DC

- Operation temperature:0-50°C

- Dimensions: 11"L x 10"W x 7"H

What is laser galvo scanner speed?

One of the key characteristics of a laser galvanometer is its deflection speed, measured in thousands of points per second (kpps). This parameter indicates how quickly the laser can move from one point to another. To unify and standardize this indicator, the International Laser Display Association (ILDA) standard test is used. During this test, the scanning speed is measured at a maximum laser beam deflection of 8 degrees. Thus, the indication ">20kpps bei 8° ILDA" means that our galvanometer is capable of scanning more than 20,000 points per second at this deflection. Such information is particularly important for users who plan to use the galvanometer in applications where high scanning speed and accuracy are required.